During my graduate studies, I had the privilege of enrolling in a course focused on compliant mechanism design. Compliant mechanisms, unlike their rigid counterparts, utilize flexible members to transfer force, motion, or energy, diverging from traditional mechanisms that rely on pinned rigid segments for such purposes. This course provided invaluable insights into the intricate world of compliant mechanism design, broadening my understanding of innovative engineering solutions.

During this course I worked on a team including two other students to design a compliant docking mechanism for spacecraft, focusing specifically on the soft capture system.

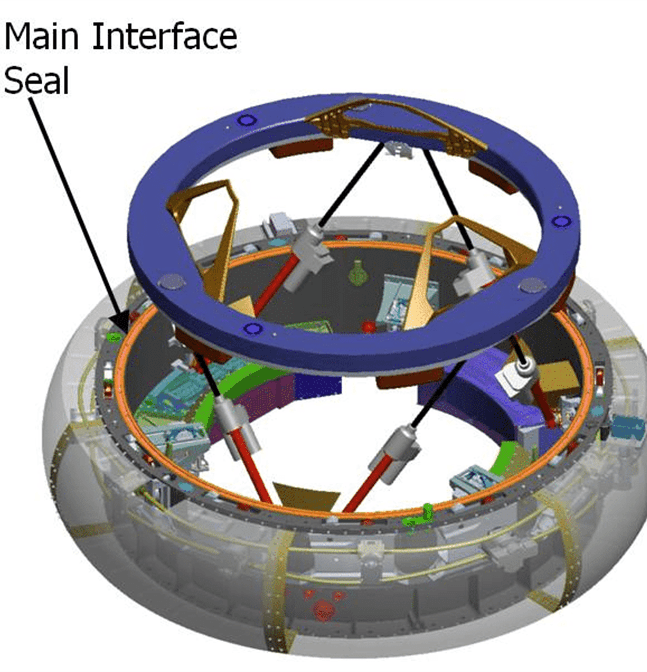

Illustration of NASA’s Docking System. – Researchgate, http://www.researchgate.net/figure/Illustration-of-NASAs-docking-system_fig1_268223478. Accessed 10 Dec. 2023.

Traditional docking mechanisms are inherently complex, often comprising numerous components. However, through the implementation of compliant mechanisms, we can streamline this complexity by significantly reducing the component count. This reduction not only decreases the potential for failure, a critical consideration in space applications, but also simplifies the docking process. By minimizing the number of moving parts and lowering spacecraft weight, compliant mechanisms offer a dual advantage. Firstly, they mitigate the risks associated with failures, and secondly, they facilitate easier access to desired orbits or enable the inclusion of additional payload. Furthermore, the incorporation of compliant mechanisms allows for the absorption of energy upon spacecraft impact with the docking structure, enhancing docking safety and efficiency.

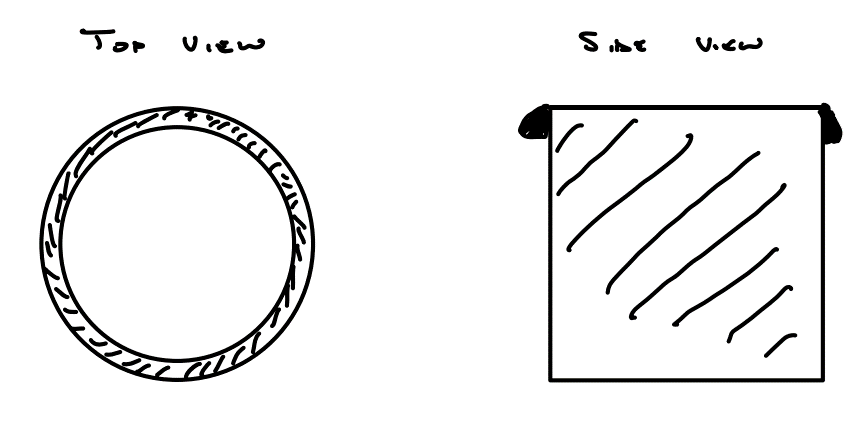

The drawing above represents the initial concept that was explored. However, this concept was ultimately not pursued further due to the challenges associated with deflecting a circle inward onto itself. Upon careful evaluation, it became evident that this approach would pose significant difficulties and wouldn’t yield an optimal compliant geometry. As a result, alternative design pathways were explored to ensure the development of an effective and feasible compliant mechanism.

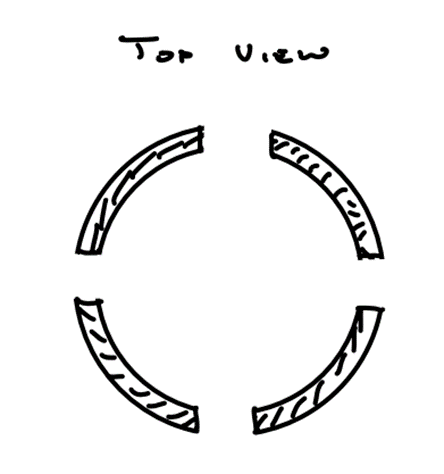

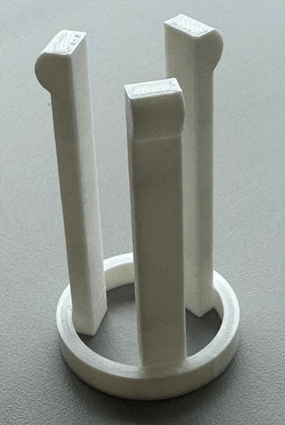

The image above showcases a second iteration of the initial concept, featuring beans designed to deflect a specific amount before clicking into a locking position. However, this concept faced challenges during Finite Element Analysis (FEA) due to the high stress concentrations observed near the bottom corners when deflecting the curved beams. Consequently, this iteration was not advanced further in the development process. This feedback from the FEA analysis was crucial in guiding subsequent design iterations towards achieving an optimized and robust compliant mechanism.

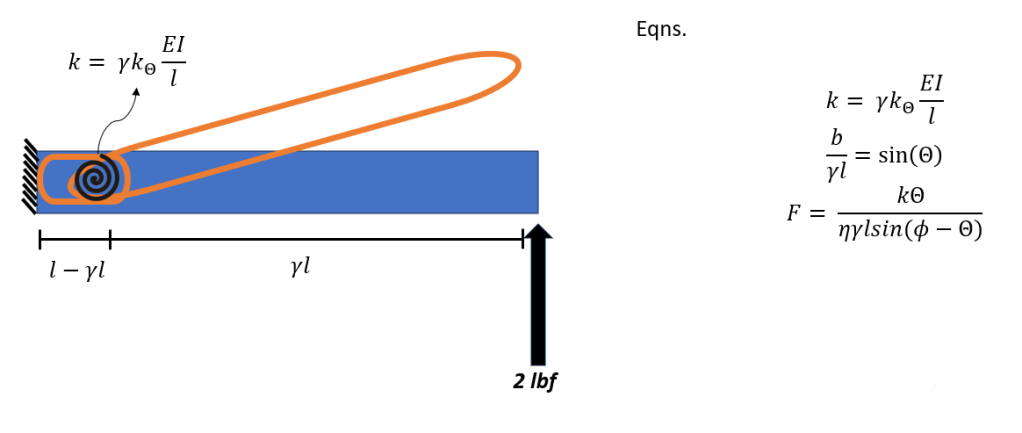

Utilizing the Pseudo-Rigid Body Model, rigid body analysis proves effective in accurately representing the deflection of flexible members. As depicted above, the final design was conceptualized as a fixed-free beam, with a torsional spring utilized to represent its stiffness. Through numerous design iterations, optimal values for insertion force, spring stiffness, and geometry were calculated, leading to the development of a compliant docking mechanism. Supplementary images and videos below provide enhanced visualization and comprehension of the design process and its outcomes.

Each of the following beams will deflect and lock into a cylindrical docking ring. This ring represents the space station, or any other structure the spacecraft is docking to. This project is just concept as it depicts how da compliant mechanism can be used for a docking mechanism.